Blog Information

- Posted By : Hussey Myers

- Posted On : Apr 06, 2024

- Views : 404

- Category : NBA

- Description :

Overview

- qidi x-max printing in high-temperature materialsAs we delve into the world of it, it becomes clear that it has a vast and complex history qidi x-max printing in high-temperature materials.

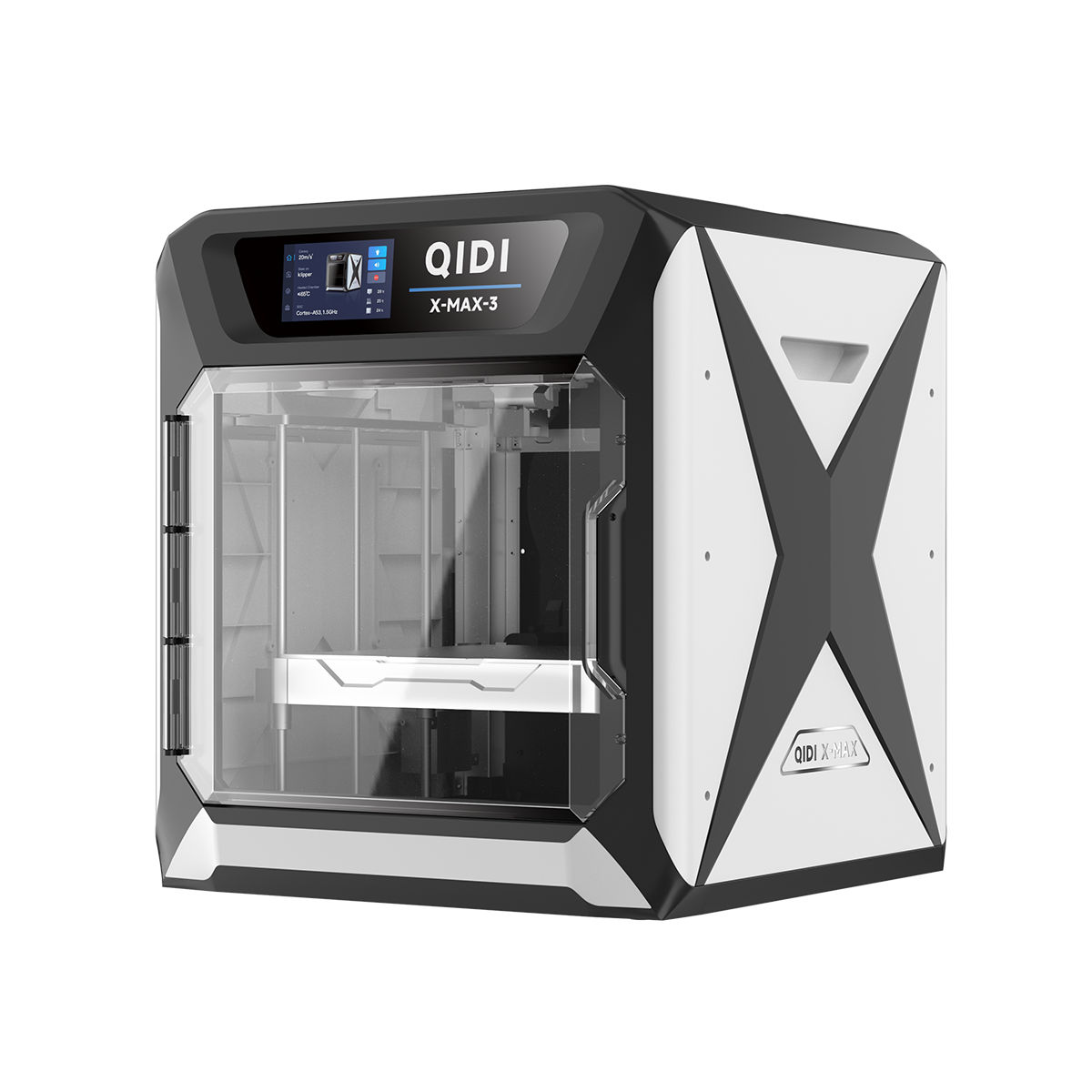

High-temperature materials printing has revolutionized the industrial world, offering endless possibilities for creating durable and heat-resistant parts. In this article, we will delve into the world of high-temperature materials printing with a focus on the Qidi X-Max printer, exploring its capabilities and the impact it has on industrial manufacturing.

The Evolution of High-Temperature Materials Printing

High-temperature materials printing has come a long way since its inception. Traditional 3D printers were limited to using low-temperature materials such as PLA and ABS. However, with advancements in technology, printers like the Qidi X-Max have emerged, capable of handling high-temperature materials like nylon, polycarbonate, and even carbon fiber-infused filaments. This evolution has opened up new avenues for industrial applications, allowing for the production of parts that can withstand extreme temperatures and harsh environments.

Challenges and Solutions

Printing with high-temperature materials presents its own set of challenges. These materials require precise temperature control and a heated build chamber to ensure proper adhesion and minimize warping. The Qidi X-Max addresses these challenges with its enclosed build chamber and dual extruders, allowing for consistent heating and improved print quality. Additionally, the printer's sturdy construction and advanced cooling systems contribute to overcoming the challenges associated with high-temperature materials printing.

Industrial Applications

The ability to print with high-temperature materials has opened up a world of possibilities for industrial applications. From manufacturing components for aerospace and automotive industries to producing tooling and molds, the Qidi X-Max has proven to be a valuable asset in the industrial world. Its capability to work with a wide range of high-temperature filaments makes it a versatile tool for producing end-use parts that meet the stringent requirements of industrial applications.

Future Prospects and Innovations

As the demand for high-temperature materials printing continues to grow, the industry is witnessing constant innovation. Manufacturers are developing new filaments with enhanced properties, pushing the boundaries of what can be achieved with 3D printing. The Qidi X-Max, with its upgradability and compatibility with a variety of materials, is well-positioned to embrace these future innovations and remain at the forefront of high-temperature materials printing in the industrial world.

In conclusion, the Qidi X-Max has proven to be a game-changer in the realm of high-temperature materials printing, offering industrial manufacturers the ability to create robust, heat-resistant parts with ease. As the technology continues to evolve, we can expect even more exciting developments in the field of high-temperature materials printing, further solidifying its place in the industrial landscape.

References