Blog Information

- Posted By : Rhea Nicely

- Posted On : Apr 06, 2024

- Views : 245

- Category : Soccer

- Description :

Overview

- Purchase QIDI X-Max for Large Prototype PrintingIf you're bored, try learning about it purchase qidi x-max for large prototype printing.

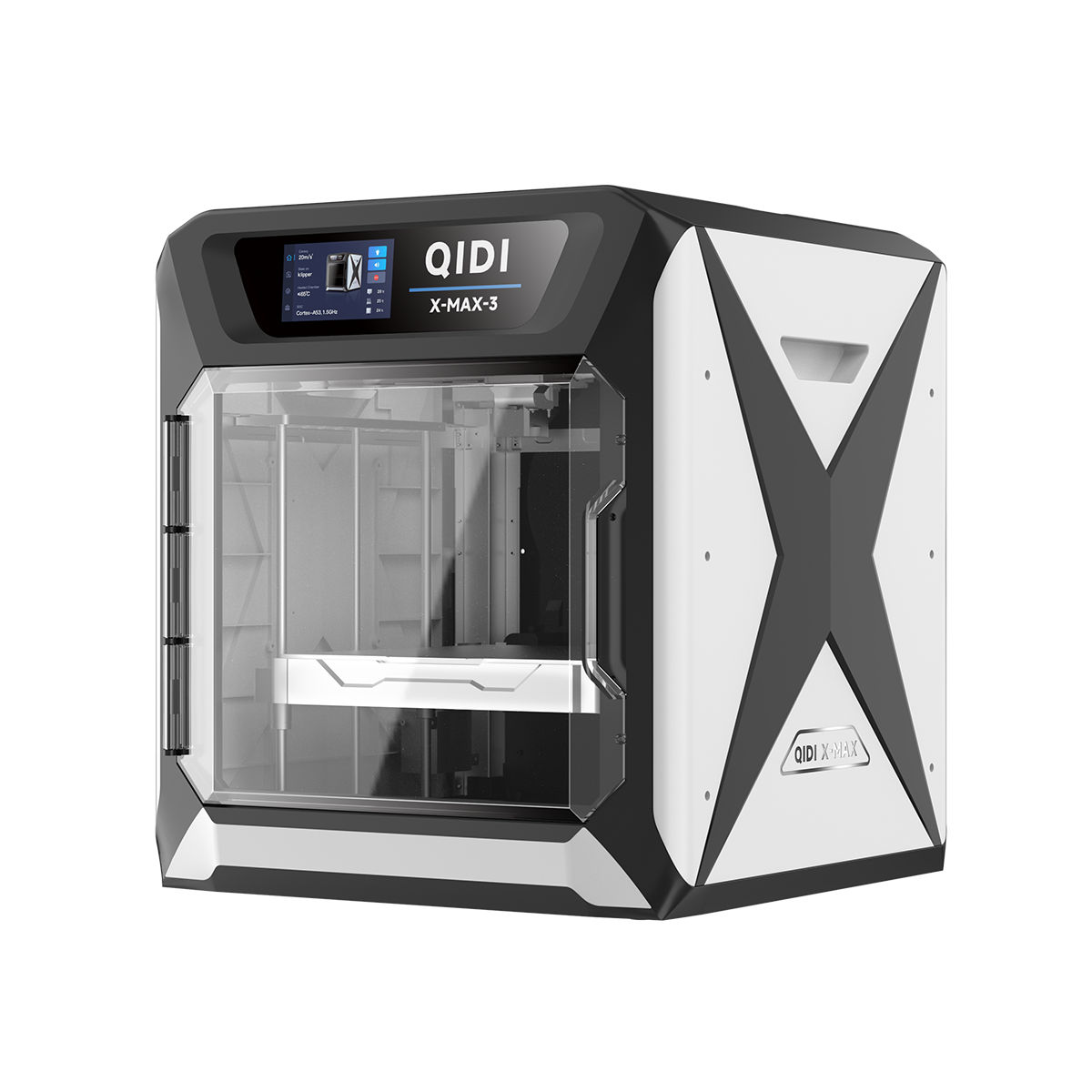

Large prototype printing has always been a challenge for industries looking to create scale models and prototypes for their products. Traditional methods often involve time-consuming processes and high costs. However, with the advancement of technology, the QIDI X-Max has emerged as a game-changer in the field of large prototype printing.

The Advantages of QIDI X-Max for Large Prototype Printing

When it comes to large prototype printing, the QIDI X-Max offers a range of advantages that make it a revolutionary tool for industries. Its large build volume and high precision allow for the creation of detailed and accurate prototypes. The printer's dual extruder system enables the use of multiple materials, opening up new possibilities for prototype design. Additionally, the QIDI X-Max is equipped with a heated print bed, ensuring better adhesion and reducing the risk of warping, especially when working with larger prints.

Enhancing Efficiency and Cost-Effectiveness

One of the key ways in which the QIDI X-Max revolutionizes large prototype printing is by enhancing efficiency and cost-effectiveness. Traditional methods often involve outsourcing the production of large prototypes, leading to increased costs and longer lead times. With the QIDI X-Max, industries can bring the printing process in-house, reducing the time and costs associated with prototype development. This not only streamlines the production process but also allows for greater flexibility in design iterations, ultimately leading to faster product development cycles.

Quality and Precision in Large Prototype Printing

Quality and precision are paramount in large prototype printing, and the QIDI X-Max delivers on both fronts. Its advanced features, such as automatic bed leveling and filament detection, ensure consistent and high-quality prints. The printer's ability to work with a wide range of materials further enhances its versatility, allowing industries to create prototypes that closely mimic the properties of the final products. Whether it's testing the functionality of a large-scale machine part or creating a detailed architectural model, the QIDI X-Max provides the precision and quality required for large prototype printing.

Expanding Possibilities in Large Prototype Printing

With the QIDI X-Max, industries are no longer limited by the constraints of traditional large prototype printing methods. The printer's large build volume and compatibility with various materials open up new possibilities for creating complex and intricate prototypes. Whether it's producing a full-scale automotive prototype or a detailed industrial component, the QIDI X-Max empowers industries to explore new frontiers in large prototype printing. Its user-friendly interface and intuitive software further contribute to expanding the possibilities in large prototype printing, making it accessible to a wider range of professionals.

In conclusion, the QIDI X-Max has undoubtedly revolutionized the field of large prototype printing. Its advanced features, cost-effectiveness, and precision have made it an indispensable tool for industries looking to streamline their prototype development process. By bringing large prototype printing in-house and offering unparalleled quality and versatility, the QIDI X-Max has set a new standard for the industry, paving the way for innovation and creativity in prototype design and development.

References