Blog Information

- Posted By : Adams Shafer

- Posted On : May 29, 2024

- Views : 410

- Category : NFL

- Description :

Overview

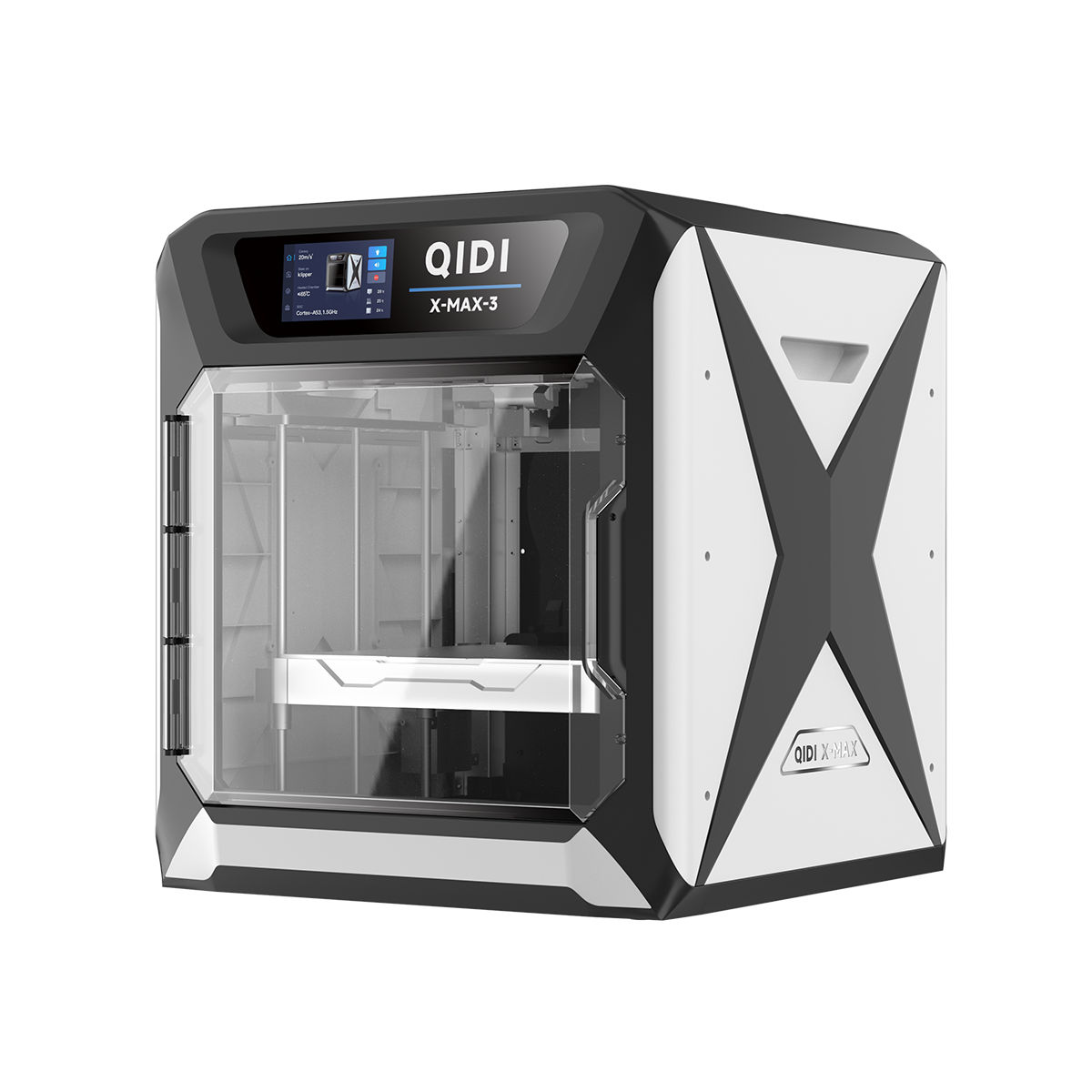

- Large 3D Printer

The Rise of Large 3D Printers

This article will give us an insight into large 3d printer.3D printing technology has been making waves in various industries, but the advent of large 3D printers has taken this innovation to a whole new level. These massive machines are transforming the manufacturing landscape by offering unprecedented capabilities and efficiencies.

Enhancing Production Speed and Efficiency

One of the key benefits of utilizing large 3D printers in manufacturing is the significant improvement in production speed and efficiency. Traditional manufacturing processes often involve multiple steps, tooling, and long lead times. However, with large 3D printers, complex parts can be produced in a single run, reducing the overall production time dramatically.

Cost-Effectiveness and Design Flexibility

Large 3D printers also offer cost-effectiveness and design flexibility that were previously unattainable. By eliminating the need for expensive molds and tooling, manufacturers can save on production costs. Moreover, the ability to create intricate designs and geometries opens up new possibilities for product innovation and customization.

Applications Across Industries

The versatility of large 3D printers makes them suitable for a wide range of industries, from aerospace and automotive to healthcare and consumer goods. In the aerospace sector, these printers are used to create lightweight yet durable components, while in healthcare, they are revolutionizing the production of prosthetics and medical devices.

Future Prospects and Innovations

As large 3D printers continue to evolve, we can expect even more groundbreaking innovations in manufacturing. From the use of advanced materials to the integration of artificial intelligence and robotics, the future of manufacturing with large 3D printers holds immense potential for transforming industries across the globe.

References