Blog Information

- Posted By : Will Moke

- Posted On : Sep 10, 2024

- Views : 227

- Category : Soccer

- Description :

Overview

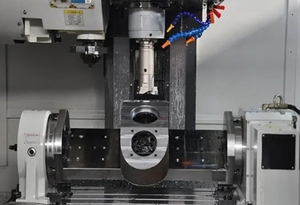

CNC machining has revolutionized the manufacturing industry by offering unparalleled precision, repeatability, and efficiency. At Ultirapid CNC Machining, we specialize in providing high-quality, custom-machined parts to industries such as aerospace, automotive, electronics, and medical equipment. Our state-of-the-art equipment and skilled engineers ensure that we meet the strictest quality standards while offering fast turnaround times.

Why Ultirapid Stands Out in CNC Machining

Our success is rooted in several factors that set us apart from the competition:

-

Advanced Technology: Ultirapid continually invests in cutting-edge CNC machining technology. With 5-axis CNC machining, we can create complex geometries that were once impossible with traditional methods. This technology allows us to machine intricate parts with tighter tolerances and fewer setups, reducing both time and cost.

-

Expert Engineers and Operators: Our team consists of experienced engineers and machinists who bring expertise in handling various materials, including metals, plastics, and composites. This expertise allows us to offer a wide range of services, including precision milling, turning, and grinding.

-

Custom Solutions: At Ultirapid CNC Machining, we don’t just provide generic solutions. We take the time to understand each client’s unique needs, working closely with them to develop custom machining strategies that result in optimal performance and cost savings.

Ultirapid CNC Turning Services

In addition to milling and other machining services, we also offer Ultirapid CNC Turning, which allows us to produce high-quality cylindrical components. Our CNC turning services are ideal for producing everything from simple shafts to more complex parts with multiple features. Whether the order is for prototypes or high-volume production, we can meet the most exacting requirements with precision.

Advantages of Choosing Ultirapid

-

Superior Accuracy and Precision: CNC machining offers higher precision compared to manual machining. At Ultirapid, our equipment ensures that each part is crafted with extreme accuracy, down to microns, which is critical for industries like aerospace and medical devices.

-

Efficiency and Cost-Effectiveness: Our CNC machines run 24/7, allowing for large-scale production with minimal downtime. The automation also reduces human error, ensuring each part meets exact specifications, thus minimizing waste and lowering costs.

-

Material Versatility: Ultirapid can handle a wide range of materials. From aluminum and stainless steel to titanium and plastics, our team has the expertise to work with materials that suit your project, whether it’s for high strength, heat resistance, or light weight.

-

Shorter Lead Times: Thanks to our advanced technology, including 5-axis CNC machining, and efficient processes, we can complete jobs faster without sacrificing quality. This means you get your parts quicker, allowing you to meet project deadlines and stay ahead of the competition.

Industries Served

Ultirapid serves a broad range of industries. In aerospace, for example, our ability to produce high-precision components with stringent tolerances is crucial for ensuring safety and performance. In the medical field, our services are utilized to create parts for surgical tools and implants, where precision is essential for patient outcomes. Automotive manufacturers rely on us for both prototyping and production of parts that must withstand harsh environments.

Conclusion

At Ultirapid, we are committed to providing superior CNC machining services, whether through 5-axis CNC machining or our specialized CNC turning. Our team’s dedication to precision, quality, and efficiency ensures that we meet and exceed customer expectations. Whether you need high-volume production or intricate prototypes, Ultirapid is your partner for top-tier CNC machining services.

-