Blog Information

- Posted By : Milliner Vasquez

- Posted On : Feb 11, 2024

- Views : 282

- Category : MLB

- Description :

Overview

- CNC Manufacturing

The Evolution of CNC Technology

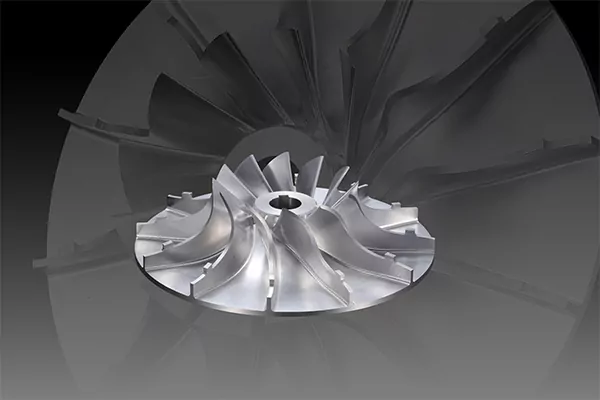

Pass by don't miss, take a look may be differentcnc manufacturing.Computer Numerical Control (CNC) has revolutionized the manufacturing industry, allowing for precise and efficient production processes. The technology has come a long way since its inception, with advancements in software, hardware, and automation capabilities. Today, CNC machines can perform a wide range of tasks, from milling and turning to laser cutting and 3D printing.

Enhancing Precision and Efficiency

One of the key benefits of CNC in modern manufacturing is its ability to deliver unparalleled precision. By following digital instructions, CNC machines can produce complex and intricate parts with minimal margin for error. This level of accuracy not only ensures high-quality end products but also reduces material waste and rework, making the manufacturing process more cost-effective.

Empowering Innovation and Customization

With CNC technology, manufacturers have the flexibility to create custom components and prototypes without the need for extensive retooling. This capability has opened up new possibilities for innovation across various industries, allowing for the development of unique and specialized products. Whether it's aerospace, automotive, or medical devices, CNC enables the production of tailored solutions to meet specific requirements.

Streamlining Production and Time-to-Market

Another significant advantage of CNC in modern manufacturing is its contribution to streamlining production processes and reducing time-to-market. By automating repetitive tasks and optimizing workflows, CNC machines can significantly shorten lead times and increase overall productivity. This efficiency is crucial in meeting the demands of today's fast-paced market and staying ahead of the competition.

In conclusion, the role of Computer Numerical Control (CNC) in modern manufacturing cannot be overstated. Its impact on precision, efficiency, innovation, and production timelines has transformed the industry and continues to drive advancements in manufacturing capabilities. As technology continues to evolve, we can expect CNC to play an even more integral role in shaping the future of production.

References