Blog Information

- Posted By : Amyotte Grant

- Posted On : Mar 07, 2024

- Views : 500

- Category : Soccer

- Description :

Overview

- CNC ManufacturingFrom its origins to its current state, it has evolved significantly cnc manufacturing.

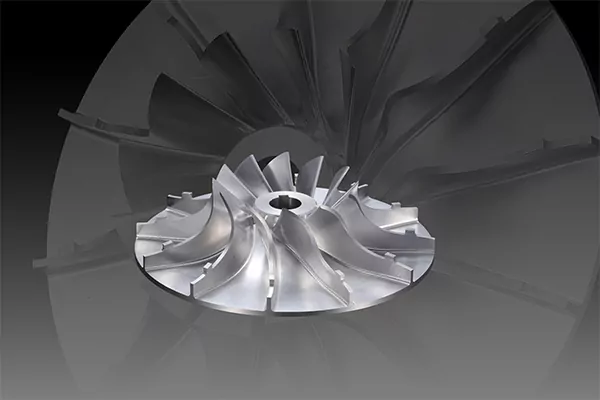

When it comes to cutting-edge tools for CNC manufacturing, the industry is constantly evolving with the latest software and hardware technologies. In this article, we will explore the advancements that have revolutionized the world of CNC manufacturing, from innovative software solutions to state-of-the-art hardware developments.

The Impact of Advanced Software

One of the most significant developments in CNC manufacturing has been the introduction of advanced software solutions. These software programs are designed to optimize the entire manufacturing process, from design to production. For example, CAD/CAM software has become an essential tool for creating intricate designs and converting them into machine-readable code. This has significantly improved the precision and efficiency of CNC machines, allowing manufacturers to produce complex parts with ease.

Simulation and Optimization

Another key feature of advanced software is the ability to simulate and optimize the manufacturing process. With the help of cutting-edge tools for CNC manufacturing, manufacturers can now simulate the entire production process to identify potential issues and optimize the workflow before the actual production begins. This not only saves time and resources but also ensures a higher level of quality in the final product.

Advancements in Hardware Technologies

Alongside software innovations, hardware technologies in the world of CNC manufacturing have also seen significant advancements. From high-speed machining to multi-axis capabilities, modern CNC machines are equipped with a wide range of features that have redefined the manufacturing landscape.

High-Speed Machining

High-speed machining is one of the most notable advancements in CNC manufacturing. With the ability to operate at incredibly high speeds, modern CNC machines can achieve faster production rates without compromising on precision. This has opened up new possibilities for manufacturers, allowing them to take on more complex projects and meet tight deadlines with ease.

The Future of CNC Manufacturing

As we look to the future, the world of CNC manufacturing is poised for even more exciting developments. With the integration of artificial intelligence and machine learning, CNC machines are expected to become even more autonomous and efficient. This will not only streamline the manufacturing process but also open up new opportunities for innovation and creativity in product design.

In conclusion, the world of CNC manufacturing is constantly evolving with the latest software and hardware technologies. From advanced software solutions that optimize the entire manufacturing process to state-of-the-art hardware developments that enable high-speed machining, the industry is experiencing a revolution that is reshaping the way products are designed and produced. With the future looking even more promising, it's an exciting time to be a part of the cutting-edge tools for CNC manufacturing industry.

References