In the realm of battery technology, two prominent players stand out: NMC (Lithium Nickel Manganese Cobalt Oxide) and LiFePO4 (Lithium Iron Phosphate). These two types of lithium-ion batteries have garnered significant attention due to their distinct properties and applications. Understanding the disparities between NMC and LiFePO4 batteries is crucial for making informed decisions in various industries, ranging from consumer electronics to electric vehicles. Let's delve deeper into the intricacies of these battery chemistries to grasp their differences and applications.

Introduction to NMC and LiFePO4 Batteries

Before diving into the comparison, let's briefly outline the fundamental characteristics of NMC and LiFePO4 batteries.

NMC Batteries: NMC batteries are composed of nickel, manganese, cobalt, and oxygen, offering a balanced combination of energy density, power capability, and longevity. This chemistry is widely utilized in electric vehicles (EVs), grid storage systems, and portable electronic devices due to its high energy density and moderate cost.

LiFePO4 Batteries: LiFePO4 batteries feature a cathode made of lithium iron phosphate, providing inherent safety, thermal stability, and long cycle life. While LiFePO4 batteries have a lower energy density compared to NMC batteries, they excel in applications where safety and durability are paramount, such as in electric bicycles, solar energy storage systems, and backup power supplies. NMC vs LiFePO4 Battery

Chemical Composition and Structure

The primary disparity between NMC and LiFePO4 batteries lies in their chemical composition and crystal structure.

NMC Batteries: As mentioned earlier, NMC batteries consist of nickel, manganese, cobalt, and oxygen. The specific ratios of these elements vary among different NMC formulations, affecting the battery's performance characteristics. NMC cathodes typically exhibit a layered crystal structure, allowing for high energy density and good cycling stability.

LiFePO4 Batteries: In contrast, LiFePO4 batteries contain lithium iron phosphate as the cathode material. The crystal structure of LiFePO4 is olivine, which offers excellent structural stability and minimizes the risk of thermal runaway and dendrite formation. This inherent stability makes LiFePO4 batteries less prone to safety hazards, making them ideal for applications requiring robustness and reliability.

Performance Comparison

When comparing NMC and LiFePO4 batteries, several performance metrics come into play, including energy density, power capability, cycle life, and safety.

Energy Density: NMC batteries typically boast higher energy density compared to LiFePO4 batteries, allowing for longer runtime and smaller form factors in portable electronics and electric vehicles.

Power Capability: NMC batteries exhibit superior power capability, making them well-suited for high-power applications such as EV acceleration and fast-charging scenarios.

Cycle Life: LiFePO4 batteries excel in terms of cycle life, with the ability to endure thousands of charge-discharge cycles without significant capacity degradation. This longevity makes LiFePO4 batteries ideal for applications requiring prolonged service life and minimal maintenance.

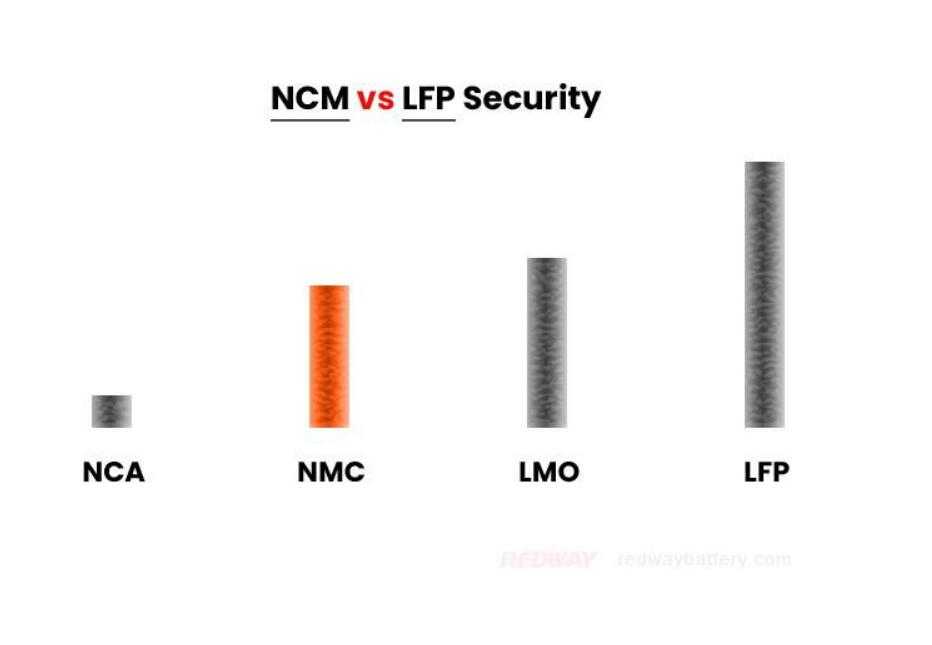

Safety: While both NMC and LiFePO4 batteries are considered safe, LiFePO4 batteries have a reputation for exceptional thermal stability and reduced risk of thermal runaway, making them the preferred choice for applications where safety is paramount.

Applications and Use Cases

The choice between NMC and LiFePO4 batteries ultimately depends on the specific requirements of the application.

NMC Battery Applications: NMC batteries find widespread use in electric vehicles, portable electronics, and grid storage systems where high energy density and power capability are critical. Their versatility and relatively low cost make them a popular choice for various consumer and industrial applications.

LiFePO4 Battery Applications: LiFePO4 batteries are favored in applications where safety, longevity, and reliability take precedence over energy density. These include electric bicycles, solar energy storage systems, uninterruptible power supplies (UPS), and medical devices where stable performance and minimal maintenance are paramount.

Conclusion

In summary, NMC and LiFePO4 batteries represent two distinct branches of lithium-ion battery technology, each offering unique advantages and trade-offs. While NMC batteries excel in energy density and power capability, LiFePO4 batteries stand out in terms of safety, longevity, and thermal stability. Understanding the differences between these battery chemistries is essential for selecting the most suitable option for a given application. Whether it's powering electric vehicles, storing renewable energy, or supporting critical devices, the choice between NMC and LiFePO4 batteries can significantly impact performance, reliability, and safety.

In conclusion, when considering the choice between NMC and LiFePO4 batteries, it's essential to weigh the specific requirements of the application against the unique characteristics of each battery chemistry. By understanding the differences and trade-offs between these two types of lithium-ion batteries, stakeholders can make informed decisions that optimize performance, reliability, and safety across a wide range of industries and applications.